Self-cleaning screens or meshs are a special type of screening, made of multiple individual or polyurethane wires. Independent cable vibrations are produced at variable frequencies to provide a good self -control effect without blocking the mesh. Compared to conventional meshes, Self-cleaning screens are characterized by lower obstruction, a long useful life and high efficiency. Due to their characteristics, Self-cleaning screens are increasingly popular in the screening industry.

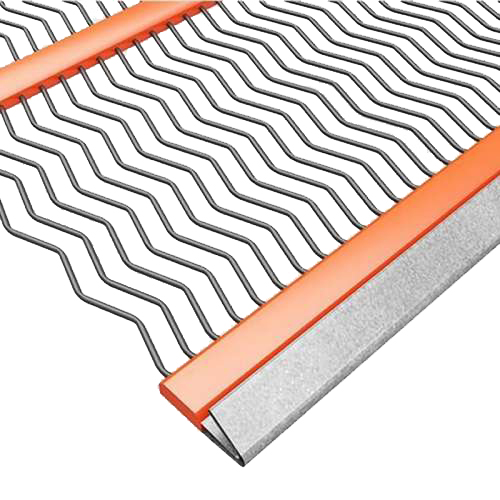

Wave Opening Self-cleaning Screen Mesh

Made with crimped wires placed parallel to each other, best used for severe blinding application, large open area

The Role of Self-Cleaning Harp Screens in Screening Efficiency

Self-cleaning harp screens are a game-changer in industries such as mining, aggregate, and recycling, where fine a

Piano Wire Screen

Red Star’ piano wire screen delivers largest screening area for rapid removal of fines In contrast to conventio

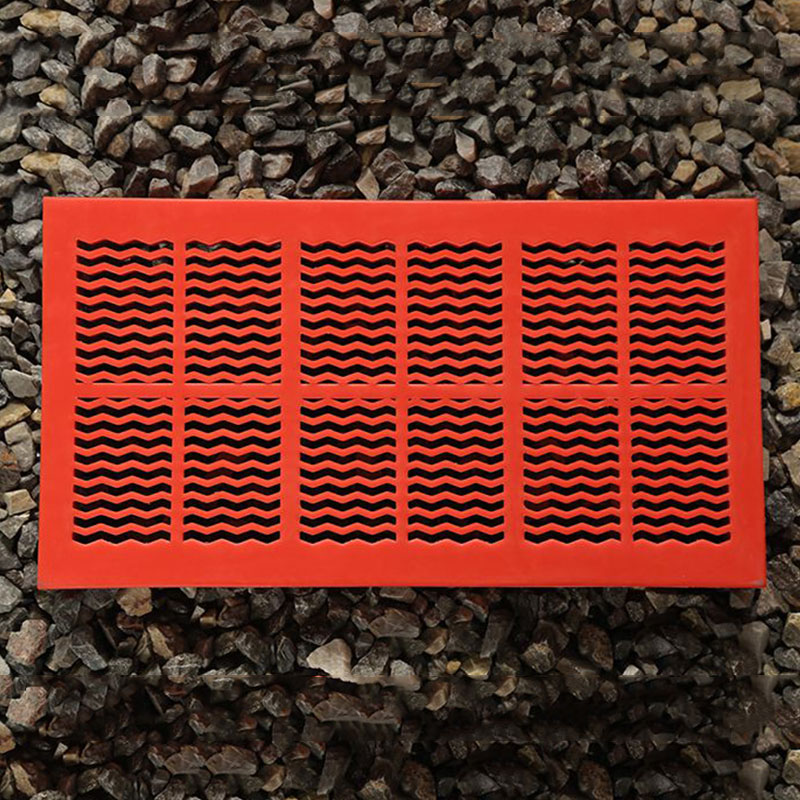

Polyurethane Self-cleaning Screen

Polyurethane self-cleaning screen from Red Star can solve the clogging problems which frequently occur in conventional polyurethane screen panels

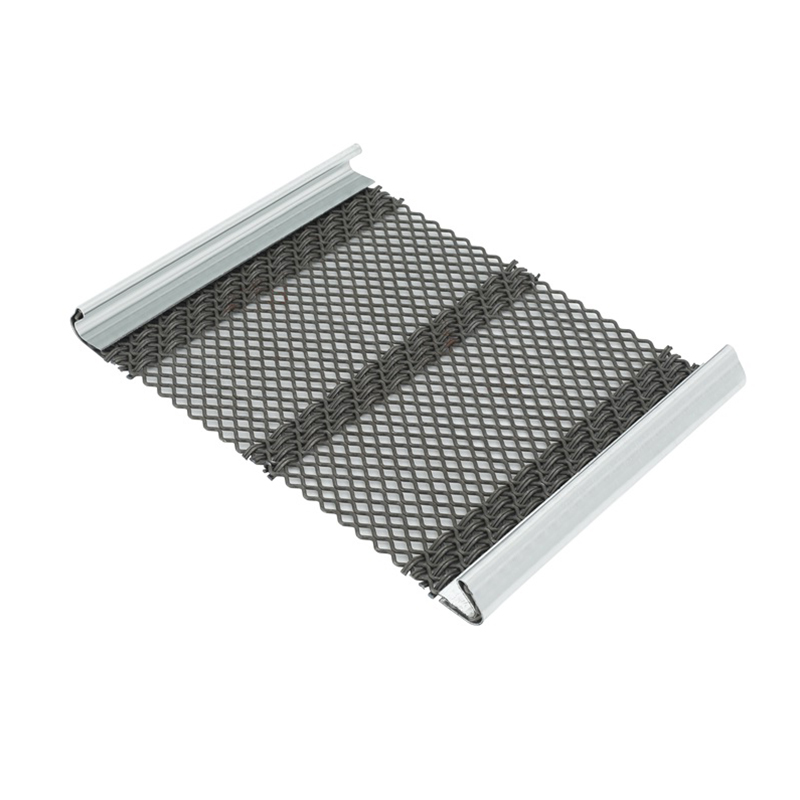

Self-Cleaning Screen (Woven Wire Cloth)

Self-cleaning screen made of woven wire cloth has an advantage of higher temperature resistance which polyurethane

Self-Cleaning Screen (Modular Screen Panel)

Unlike conventional tensioned wire mesh that requires more machine downtime due to replacement of screens, the mod

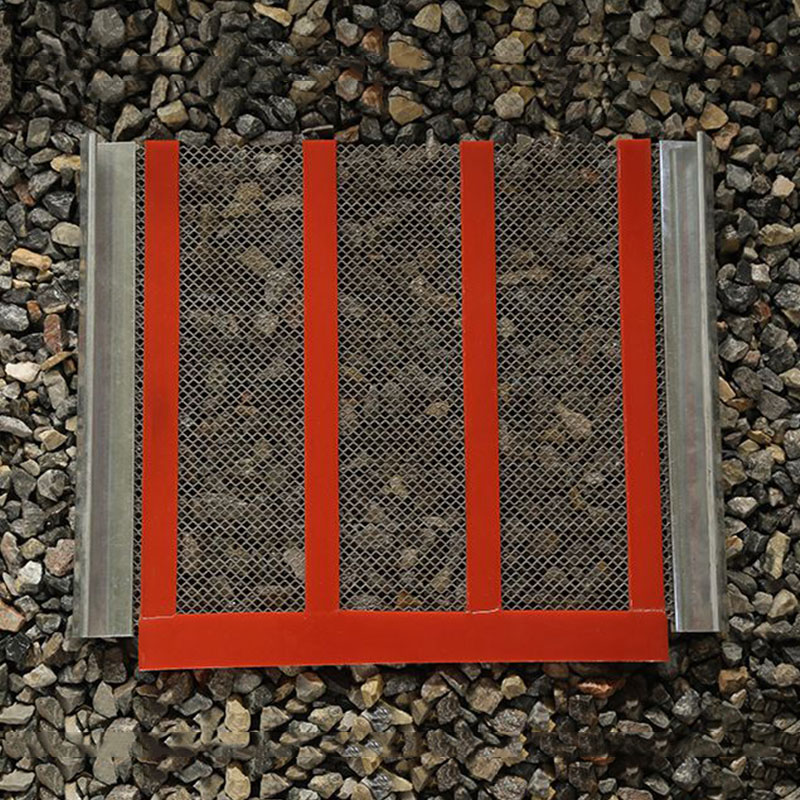

Tensioned Self-cleaning Screen

Tensioned self-cleaning screen is characterized by smooth and flat surface, its wear life is 3 times that of com